The ISA-95 models have different purposes in describing the functions and information flows in a factory. In several steps all models are filled in to define a fully integrated MES system.

Step 1: Activity Model

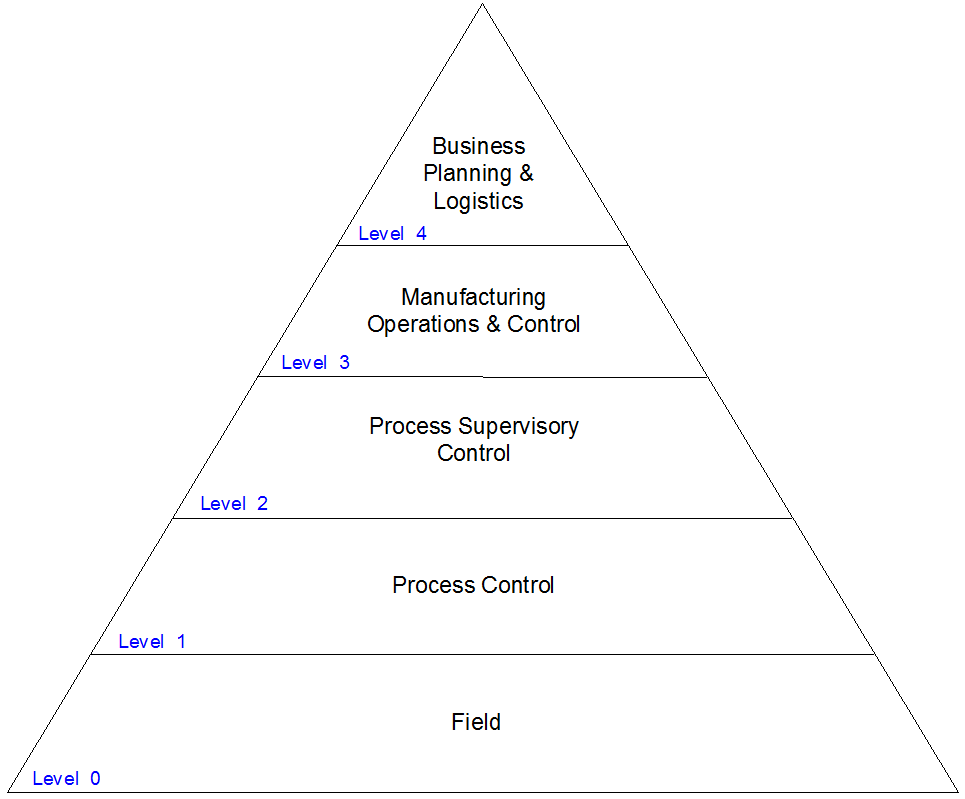

The standard uses the model for Computer Integrated Manufacturing (CIM). It defines the following levels:

- 4. Business Planning & Logistics

- 3. Operations Management & Control

- 2. Supervisory Control

- 1. Process Control

- 0. Instrumentation

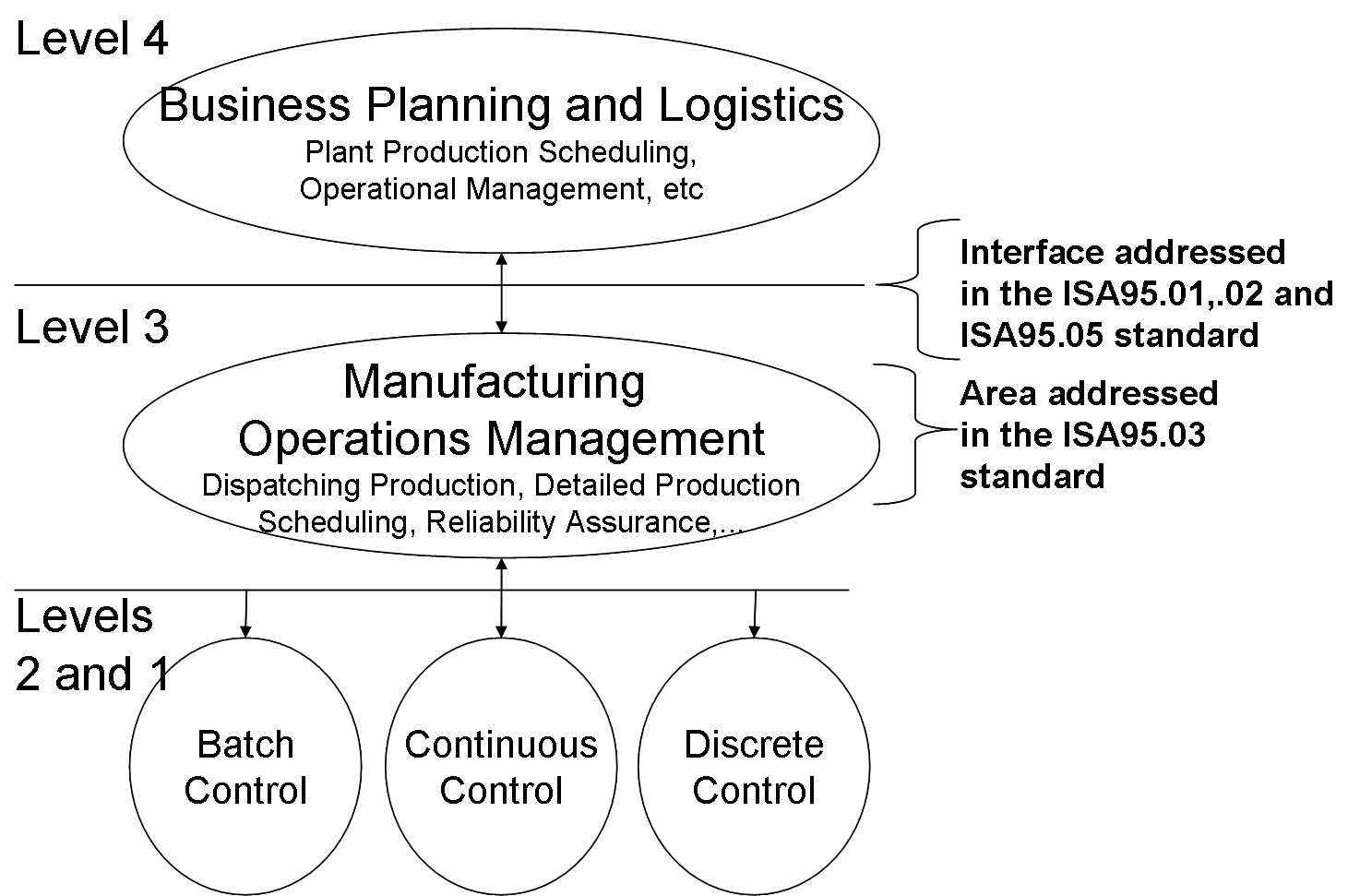

The standard describes the information exchange between Level 4 and Level 3 in Part 1 and 2. Level 3 is described in Part 3.

This model is used to create a global inventory of activities, users and systems in the layers 3 and 4. In this way an impression is created quickly what the production is done within the various departments.

The standard clearly indicates which activities at what level belong. Overall one can say that an activity belongs to level 3 if the activity is essential for:

- product quality

- safety

- legislation

- reliability of the plant

All other management activities in the area belong to level 4. These activities are often more comprehensive over time. As an example, the short-term planning (eg per week) belongs to level 3, while the longer-term planning belongs to level 4

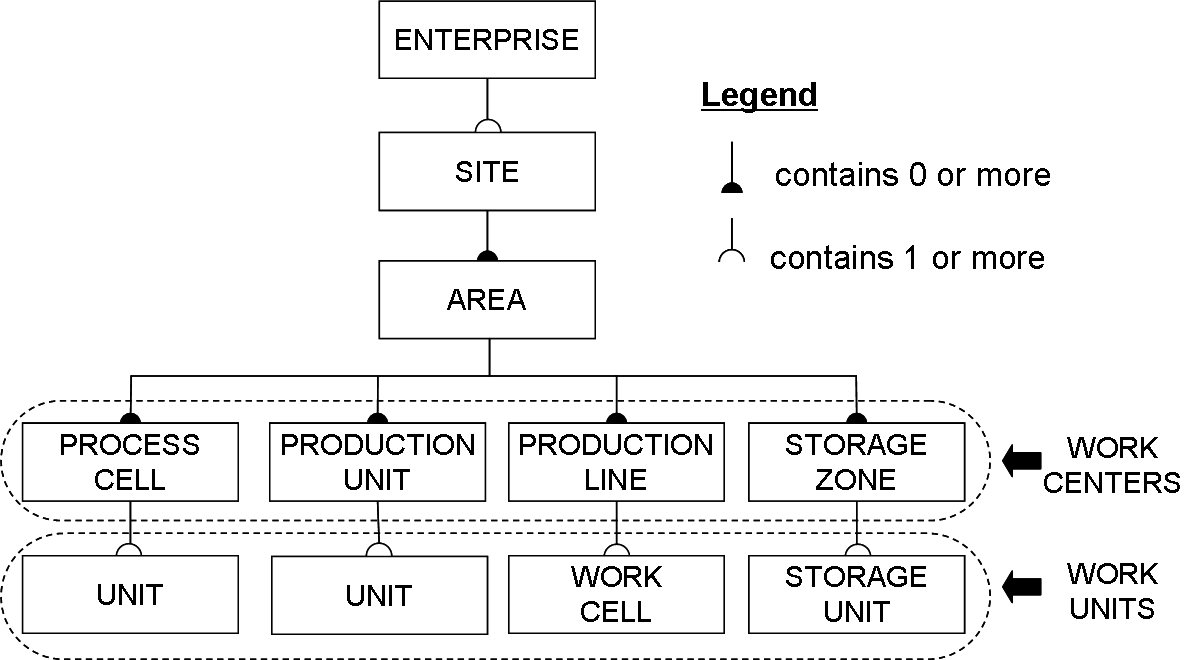

Step 2: Equipment Model

Using the Equipment Model Hierarchy model, we identify the physical layout of the factory. The model is similar to the equipment design in ISA-88, but ISA-95 focuses on the upper layers of the equipment (until work centers an work units) and it includes non-batch units. The developed model is used again in the definition of the object models of MES.

The developed model is used again in the definition of the object models of MES.

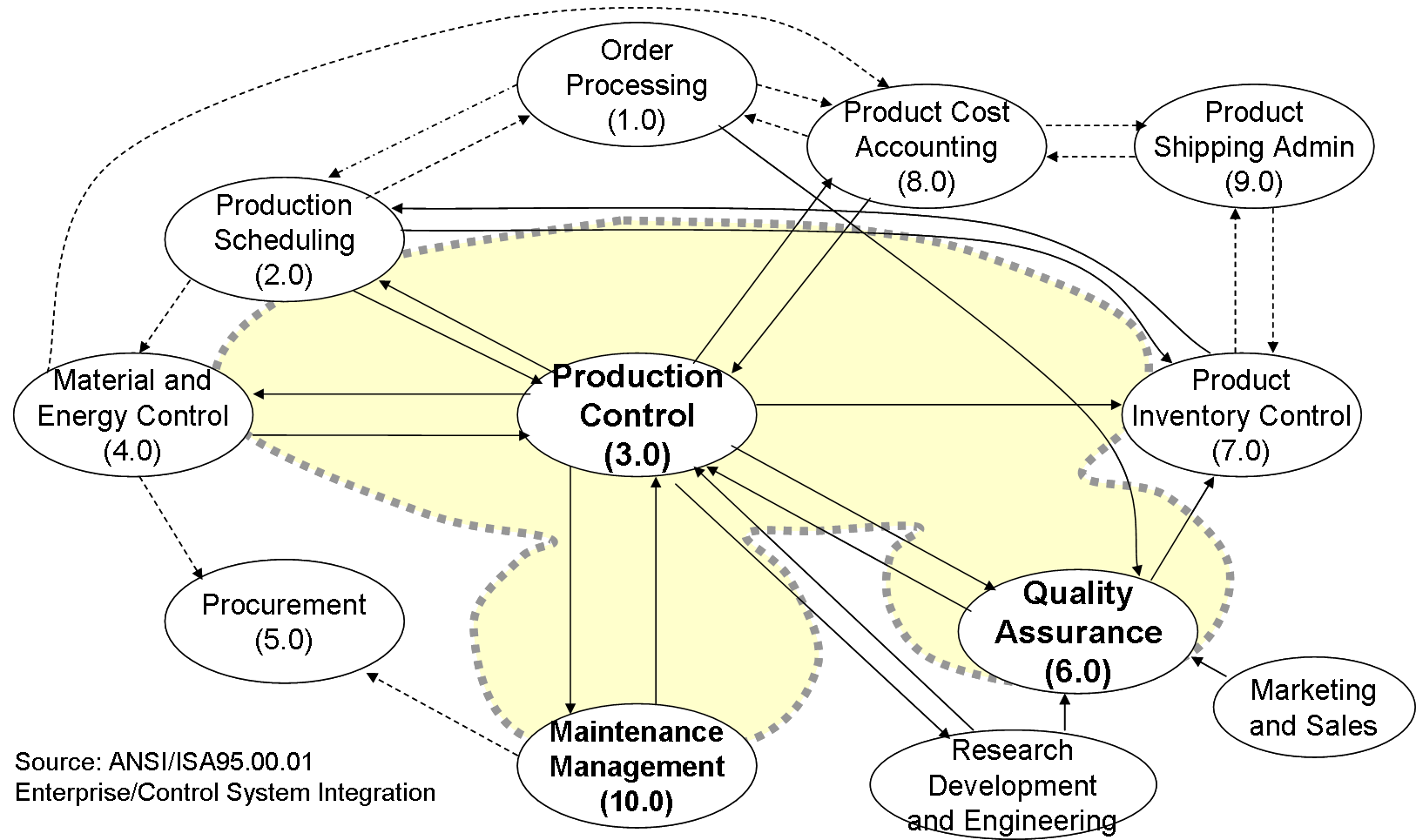

Step 3: Functional Model

The functions of the above Functional Model are mapped using the table below. It is further indicated where the various functions of the model used and who is responsible for these functions. Furthermore, they shall state whether those features are critical to the implementation of the production. Using this criterion decisions on which parts should be automated. On this basis, can display a suitable system or combination of systems can be chosen.

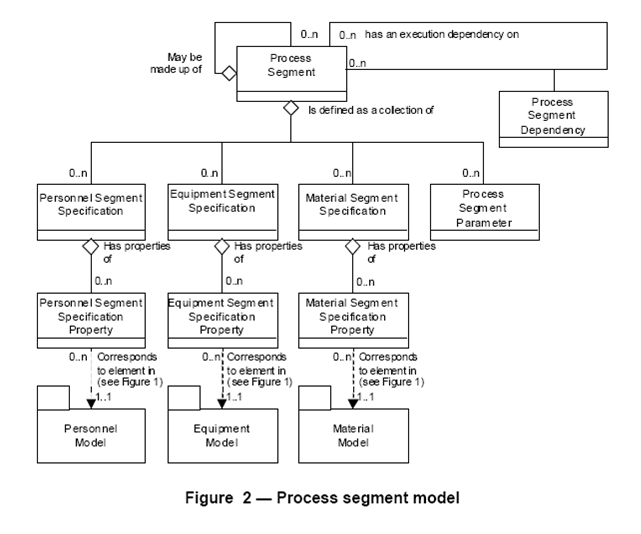

Step 4: Object Models

To design the features in level 3, object models are used, of which one is shown below.

In defining these models, all information flows in level 3 mapped. This information can be used in the design of MES applications, such as a scheduling tool. If there MES packages are used, which are based on the ISA-95 standard, the results of these models directly entered as configuration information of the package. The following models should be developed for this step:

- Personnel

- Equipment

- Material

- Process Segment

- Product Segment

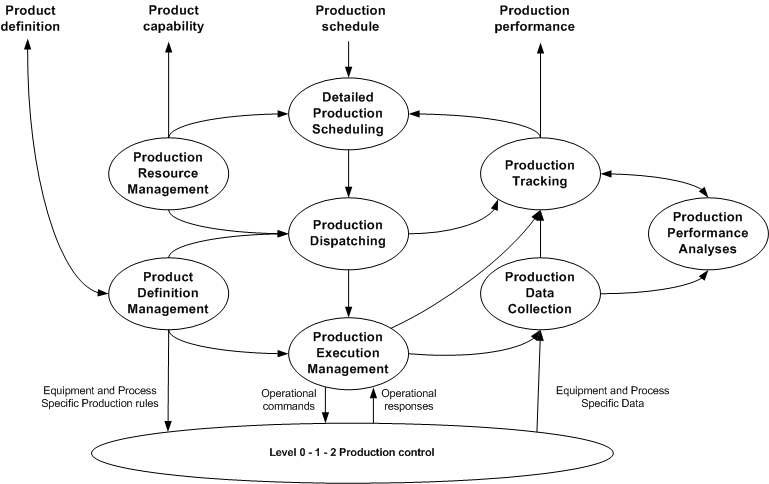

Step 5: Functional Model - Information flows

In this step, the 31 information flows identified in previous Functional Model mentioned. Define table with details for each information flow, using ISA-95.02.

Step 6: Activity Models level 3

Above Activity model is used for all functions in the MES layer. This definition is done using four models: product definition information, product capability information, product information and product performance schedule information. Below is one of the models depicted. Using these data MES packages may be selected to perform certain functions.